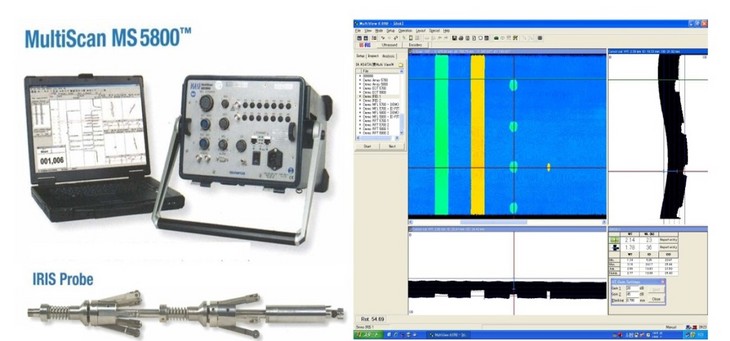

Internal Rotary Inspection System for Boiler Tube

What is IRIS?

IRIS is a thickness measurement method for thickness of tubes using water.

It is possible to conduct the measurement for the thickness of the entire tube by rotating ultrasonic waves

with a turbine inside the tube. Our latest system is able to measure it on a real-time basis while recognizing the thickness condition of the entire tube.

What is good about IRIS?

・IRIS enabled to measure a large part(any part of a tube can be measured),not by a pinpoint,

so we can comprehend the diminution conditions more precisely ever.

・Real-time monitorizing is realized.

・One tube can be inspected in only 5-10 minutes.

・Measurable for any tubes with dia. 18.0mm to 76.2mm.

・Pitting(3Ф, depth more than 1mm) can be detected.

・Capable to distinguish the inside corrosions and the outside corrosions.

・Capable to measure at afloat.

・Capable to measure the edge of a tube.

・Boiler maker suggests IRIS for inspection of boiler tubes.

How to reduct the total cost of IRIS

①Cleaning the boiler carefully.

Because it makes measurement speed per tube faster!

②Conduct the measurement as well planned.

※Conduct the measurement by dividing into several times from the early age of vessels.

Because if the condition of the boiler tube is not good, any actions can be taken at an early stage!